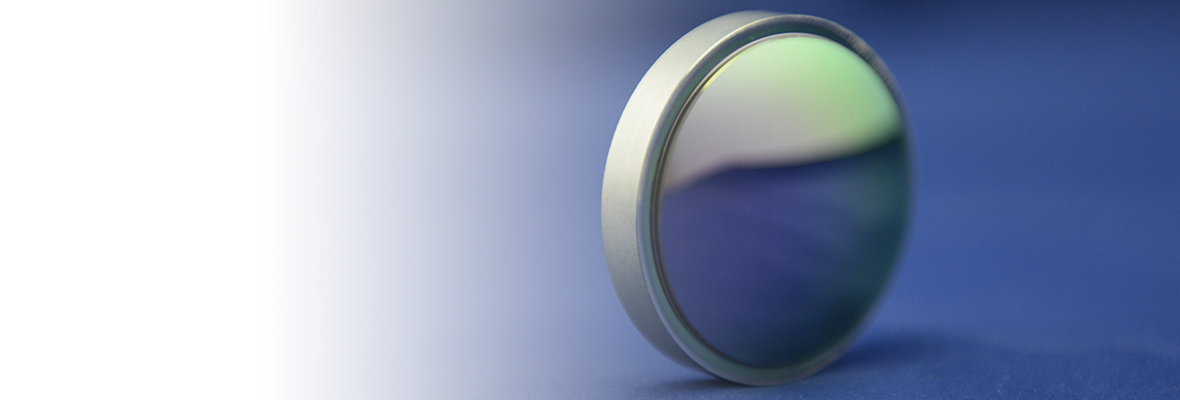

Thin Films

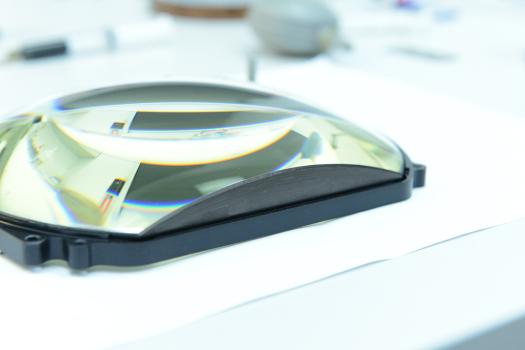

The department focuses mainly on research into new ways of designing and depositing thin layers with unique features, development of instrumentation and methods for controlling the deposition process, and on material and structural research of layers.

Team and equipment

- researchers with expertise in electronics, automated control, and measurement techniques; lab technicians responsible for the preparation of samples prior to application of layers

- Ph.D. students and students of the final year of their Master's degree program dealing with topics of deposition and characterization of special dielectric layers

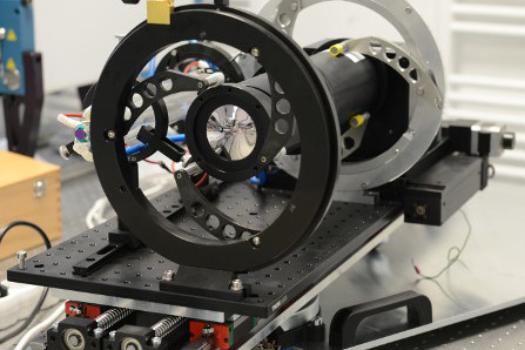

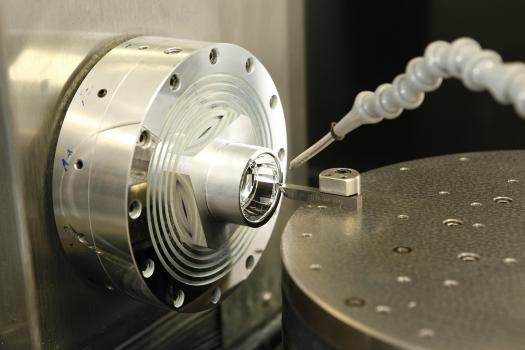

- five vacuum chambers with evaporation- or sputtering-deposition technology (e-beam, IBAD, DC magnetron, IBS)

- a set of instruments for the analysis of optical properties of layers (UV-VIS-IR spectrometry, spectroscopic ellipsometry) allowing non-destructive characterization of unknown or not fully described thin film systems

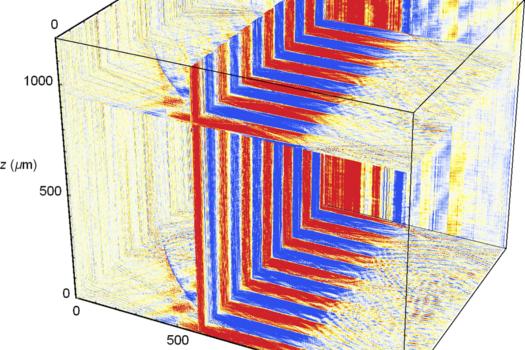

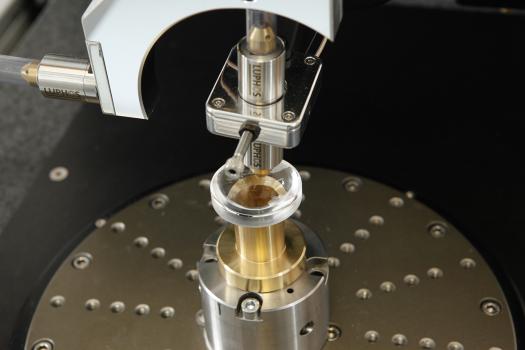

- measurement of surface properties of layers by means of white light interferometry (WLI) and atomic force microscopy (AFM)

- software tools for thin film design and theoretical analysis of their properties (Film 2000 and OptiLayer); non-standard tasks are solved by our own codes in VisualC ++ and Matlab

- instruments for control and automation of deposition systems – the ControlWeb soft-PLC system, DataLab hardware devices, National Instruments, and in-house designed electronics

Activities

- design of thin-film systems – research into optimal design of layer stacks and processes of thin-film deposition with application in VIS and IR fields; new approaches to homogeneity control

- research into absorption in thin-film systems with application in coatings for high power laser systems

- research into absorption in thin films in MWIR and LWIR spectral bands and into structures suppressing the effects of water vapours on the optical parameters of layers

- characterization of thin-film systems (ellipsometry, spectrometry) with the possibility of using destructive analysis techniques in external affiliated facilities

- development of control systems, monitoring systems, and power supplies for vacuum deposition, especially for the control of non-standard deposition processes (ferroelectric and mixed-material thin films)

- prototype production of special thin films and design of thin-film systems based on customer requirements incl. simulation of deposition yield and optimization according to the nature of the selected deposition technology

Projects

- AIRBUS TIRI = Technology Pre-development of Thermal Infra-Red Imager

- Galium Phosphide prepared by vertical cooling gradient technology as a base material for infrared sensor optics – anti-reflective layers for GaP based optical systems

- Pump Modules for High Power Fibre Lasers – Development of antireflective coatings for optical components of laser modules and antiadhesion coatings for a moulding process designed to accurately mould these optical elements

Cooperation

The department has entered into cooperation with R&D institutions both abroad (e.g. Fraunhofer Institute, Germany or Lund University, Sweden) and in the Czech Republic, e.g. University of West Bohemia (Faculty of Applied Sciences), Masaryk University (Faculty of Science), Technical University in Liberec (Faculty of Mechatronics, Informatics and Interdisciplinary Studies), Institute of Physics of the CAS, or Applic, s.r.o. Liberec.

Contact

Ing. Jan Václavík, Ph.D.

Tel.: +420 487 953 902

Mob.: +420 608 043 898

Email: vaclavik@ipp.cas.cz